More from this brand

Technical data

| Attributes | |

| ARTICLE | 48001070 |

| SIZE L/W/H | 1360/ 2360 / 2670 |

| Temperature | -10/+40°C |

| Model | CL3/1323 |

| CAPACITY | 3 trolleys for 600x800 trays |

| NOTES | Included: module for connection to the GEMM-Cloud service; USB port Product charge: 225kg Machine supplied not assembled PLUG-IN SYSTEM |

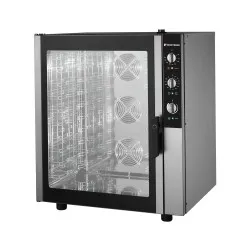

Cutting-Edge Pastry Retarder-Proofing Cabinet

The interior finish is made of AISI 304 18/10 stainless steel sheets, ensuring high hygiene levels, corrosion resistance, and easy maintenance. The exterior is covered with a "plasteel" grey sheet, combining mechanical strength with a modern and aesthetic design, providing resistance to everyday wear.

The internal capacity is adapted for trolleys with 600x800 mm trays, allowing for convenient and efficient placement of various product batches. The unit is supplied with a ramp for trolley entry; however, trolleys are not included.

The thermal insulation is 80 mm thick, ensuring high energy efficiency and stable temperature maintenance. The floor is reinforced with stainless steel and additionally insulated with a 60 mm thick layer, guaranteeing durability and resistance even under intensive load conditions.

The cooling system operates with indirect and gentle ventilation, preventing the negative impact of direct cold air flow on products. It ensures uniform temperature and humidity, maintaining product structure, freshness, and quality. The fan speed is precisely regulated at all stages, adapting air circulation to specific needs.

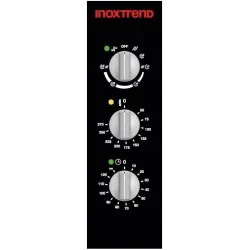

Control is via a 7-inch touch panel, providing a multifunctional and multilingual user interface, making operation intuitive and convenient for staff at various levels. An integrated Wi-Fi monitoring system and USB port are available for data management and recording.

A steam generator maintains the necessary humidity level during fermentation processes, improving the quality of dough and pastry products. The interior is equipped with LED lighting, ensuring good visibility. The condensing unit is integrated into the equipment's body, optimizing space utilization and simplifying maintenance tasks.

The unit can reliably operate in ambient temperatures up to +40 °C, ensuring stable and high-quality performance even in the most demanding working conditions.