An Efficient and Sustainable

Solution for Your Kitchen

Calculate the cost of your project.

Free and takes only 3 minutes.

Free and takes only 3 minutes.

Alise Kalniņa

Planning a professional HoReCa project? Not sure where to start?

Creating a professional kitchen and other HoReCa projects requires more than just purchasing the right equipment. It requires ensuring an efficient workflow, choosing energy-efficient equipment, adhering to general safety requirements, and avoiding excessive costs.

We offer customized solutions that meet your unique needs. With over twenty years of experience, we know how to design a kitchen that maximizes efficiency, includes the necessary inventory, and complies with all health and safety regulations.

We offer customized solutions that meet your unique needs. With over twenty years of experience, we know how to design a kitchen that maximizes efficiency, includes the necessary inventory, and complies with all health and safety regulations.

Calculate the cost of your project.

Free and takes only 3 minutes.

Free and takes only 3 minutes.

★ ★ ★ ★ ★

We have served more than 4,000+ customers, find out what they think about BHS

Quick help in emergency situations

Scheduled maintenance programs

Original manufacturer's spare parts

Making unique parts

1 year spare parts warranty

Spare parts delivery within 24 hours

BHS Design Process

Project Evaluation

Together we assess your business’s specific needs and goals, taking into account your location, budget, and volume of operations. We analyze your space, menus, and workflow to understand what is needed for your ideal outcome.

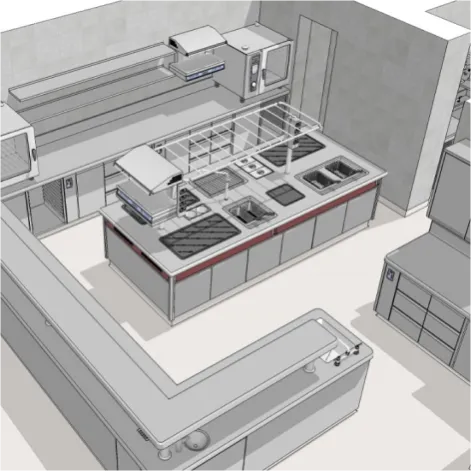

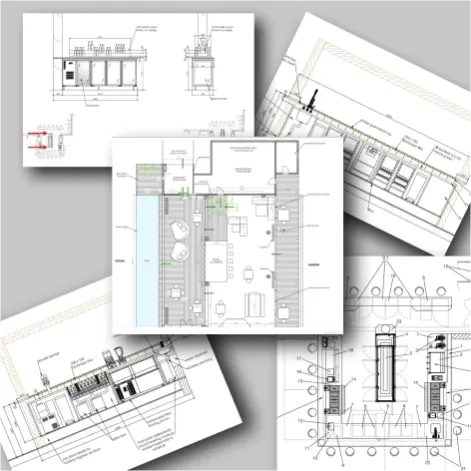

Kitchen Plan Development

We create initial design plans that optimize workflow and space utilization, ensuring the best layout for your kitchen. Our designs ensure efficiency, functionality, and sustainability.

Detailed Planning and Equipment Selection

We select the most suitable equipment to suit your kitchen specifications, functions and budget. Our plan ensures optimal layout and energy efficiency.

Equipment Installation and Testing

We will create a custom kitchen design that meets the specific requirements and scale of your business. Whether it's a restaurant, hotel or café, we create solutions that increase efficiency and satisfy your customers.

Technical Support and Training

We provide employee training and technical support so your team can take full advantage of your new equipment. Our team will help you realize the full potential of your new kitchen.

-150x150w.webp)

-471x471.webp)