The role of showers in convection oven cleaning

Showers for cleaning convection ovens help foodservice operations maintain consistent work quality and reduce cleaning time. In busy kitchens, ovens run continuously, so quick rinsing after each cycle is essential to prevent burnt residue, grease buildup and detergent traces.

Interior walls, ventilation channels and steam generator zones are usually the areas where the most residue accumulates. A shower makes it easier to reach these spots and keep them clean even when there is no time for a full automatic wash. Stable pressure improves rinsing results and helps maintain workflow without increasing operator fatigue.

This equipment is valuable in kitchens with high hygiene requirements, such as preparing meat dishes, pastries or steaming stocks. Quick rinsing can also help extend oven durability by reducing long-term buildup risks.

Main shower constructions and differences

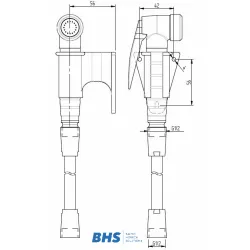

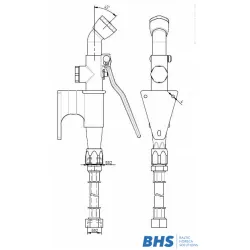

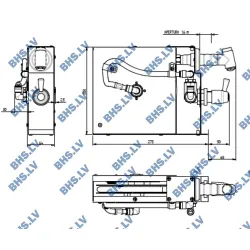

Professional kitchens use several shower types designed for different oven sizes and cleaning intensity. Basic handheld showers provide a steady water flow and work well for smaller ovens or light rinsing between cycles.

Telescopic showers allow easier access to deeper areas, especially in large ovens. Flexible hoses ensure smoother movement and reduce resistance while working during long shifts.

Many models feature ergonomic handles for a secure grip. Stainless steel and heat-resistant fittings offer long-term durability. Some showers include adjustable flow settings, allowing operators to choose between gentle rinsing and stronger pressure for removing burnt spots.

Parameters to consider

Professional kitchens typically evaluate several parameters when selecting a shower. Hose length determines how easily all oven areas can be reached, especially in larger models. Flexible materials help maintain mobility without restricting the operator.

Water pressure directly affects rinsing efficiency. Too low pressure leaves residue, while excessive pressure may cause splashing. Optimal flow ensures effective yet controlled rinsing.

Material quality is crucial for durability. Stainless steel, heat-resistant polymers and flexible hose materials ensure long-term performance. Temperature tolerance should be checked, as convection ovens often operate between 30 and 250 °C.

Compatibility with the oven model is essential. Manufacturers use different connection types, so the shower must match the installation point. Available space in the kitchen should also be considered for convenient storage.

- Stable water pressure for effective rinsing

- Suitable hose length and flexibility

- Heat-resistant materials for long-term use

- Reliable connections and oven compatibility

Maintenance and operation

Daily maintenance ensures stable water flow and reduces clogging risk. After use, the shower should be rinsed with clean water to prevent grease and detergent accumulation. In areas with hard water, more frequent nozzle cleaning helps reduce scale buildup.

Hoses and fittings should be checked regularly, especially in high-intensity environments. Cracks or wear on the hose indicate the need for replacement. Mild detergents help protect materials and keep surfaces smooth.

Many kitchens implement weekly maintenance routines, checking nozzle cleanliness, handle performance and connection safety. This helps maintain stable flow and reduce downtime during peak periods.

BHS service and technical support

BHS provides technical support for kitchens using showers for convection oven cleaning. The company offers spare parts such as handles, fittings, hoses and seals, helping restore equipment quickly in demanding environments.

Technical specialists assist with installation, safe operation and compatibility with various oven models. They help choose the most suitable solution based on oven size, available space and cleaning frequency.

Fast delivery of spare parts supports smooth kitchen workflow and helps minimize downtime during busy seasons.

Frequently asked questions about convection oven cleaning showers

What hose length is suitable for large convection ovens?

Long and flexible hoses are preferred to reach all oven areas, including deeper chambers and ventilation zones.

Is the shower handle suitable for high-temperature work?

Many models are made from heat-resistant materials that maintain stability during temperature fluctuations.

How to check if a shower is compatible with my oven?

Compatibility is usually determined by the connection type. It is advisable to check manufacturer documentation and the installation area.

How to prevent pressure loss during operation?

Regular nozzle cleaning and hose inspection help prevent clogging and maintain stable water flow.

How often should a shower be serviced in a professional kitchen?

In intensive environments, maintenance is recommended at least once per week to detect wear or damage early.