Use of pedal-operated faucets in professional kitchens

Pedal-operated faucets simplify work in wash areas by allowing the water flow to be activated with a foot press. This lets the operator hold dishes, utensils or pans with both hands and rinse quickly without interrupting the workflow. In busy kitchens this function reduces unnecessary movements and helps maintain a steady pace.

Restaurants, canteens and production kitchens often use pedal control to maintain cleanliness and reduce contact with contaminated surfaces. It is especially useful in situations where frequent hand rinsing is needed during food preparation.

Features and operating principle

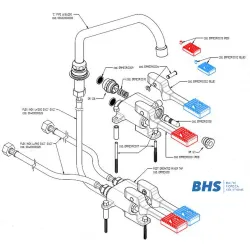

A pedal faucet responds to foot pressure and opens the water supply only as long as the pedal is pressed. This level of control can reduce water consumption and ensures precise flow timing. Some models use a mechanical valve, while others rely on a mixing chamber that combines hot and cold water.

Short, controlled water bursts are practical for rinsing dishes, cleaning tools and washing hands between preparation steps. Pedal operation also helps keep work surfaces clean, as they are not constantly touched to adjust the flow.

Materials and quality criteria

Pedal faucets for professional use are usually made of stainless steel or metal with chrome plating. These materials withstand heavy mechanical use, moisture and cleaning agents. Connection hoses are made from heat-resistant, flexible materials that provide long-term reliability.

The pedal design is an important factor. Metal pedals typically offer firmer pressure feedback and better durability. Ceramic valves help maintain a smooth flow and precise mixing, which is important in kitchens where water temperature changes often.

The installation point should be selected so the pedal is easy to reach and does not create a tripping risk in a dynamic work area.

What to check before purchase

Before purchasing, it is worth evaluating several technical aspects to ensure the pedal faucet fits the wash area and withstands daily use.

- Compatibility with the sink depth and shape to avoid splashing.

- Mounting type and connection point: floor, wall or under-counter installation.

- Pedal resistance and sensitivity under intensive working conditions.

- Flow capacity and available water pressure in the kitchen.

- Material durability, especially at joints and hoses.

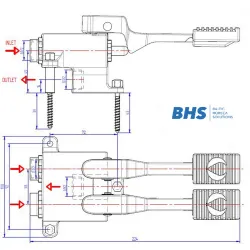

BHS service and technical support

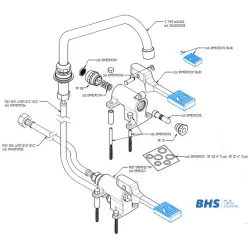

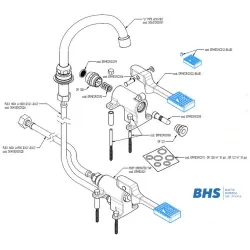

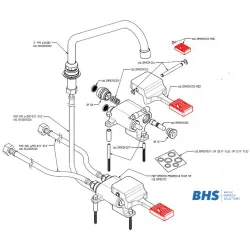

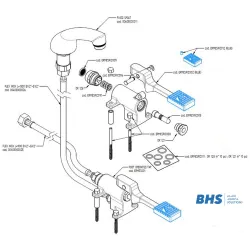

BHS provides professional service for pedal faucets and wash-area equipment used in HoReCa environments. Spare parts for mechanical valves, connectors and hoses are available to keep equipment running reliably.

The technical team helps select the right solution for different sinks and workstations and provides support with installation and maintenance. This reduces downtime risks and helps maintain a stable kitchen workflow.

Frequently asked questions about pedal-operated faucets

How does a pedal faucet improve hygiene in a kitchen?

It reduces the need to touch handles with dirty hands, which is especially useful when working with raw ingredients.

Does a pedal faucet fit any sink?

It is generally compatible with many sinks, but dimensions and connection points should be checked before installation.

How durable are pedal mechanisms?

Durability depends on the materials and usage intensity, but metal pedals with ceramic valves typically offer longer service life.

Can pedal faucets be used for intensive dishwashing?

Yes, they are often used in busy wash areas where quick and precise flow control is required.

How difficult is the installation?

Installation is usually simple if the correct connection points are available, but professional service provides a more reliable result.