Use of two-hole faucets in HoReCa kitchens

Two-hole faucets in professional kitchens support stable and easily controlled water flow during daily work. Restaurants, cafés and catering businesses rely on these solutions in preparation areas, dishwashing stations and auxiliary sinks where continuous water flow is required. Separate hot and cold handles allow precise temperature adjustment that helps with washing vegetables, rinsing ingredients and cleaning heavily soiled cookware.

Two-hole installation. These faucets are mounted on sinks or worktops with two pre-cut holes, ensuring firm positioning and reducing movement during intensive operation. This setup is especially useful when several staff work in the same area and the faucet is frequently opened or closed with greater force.

Compatibility with professional sinks. Two-hole faucets integrate well with stainless steel sinks used in HoReCa environments. Appropriate spout height and rotation angle make it easier to work with tall pots, GN containers and pans while keeping water inside the sink area.

Construction types and technical features

The range includes tall curved spouts and more compact models for smaller sinks. Tall spouts create enough clearance for large pots, vertical dish racks and large pans, while low spouts suit tight spaces or installations under shelves.

Swivel spouts. Many professional faucets feature a swivel spout that simplifies switching between two adjacent sinks or separate zones within a single basin. This improves workflow from washing to rinsing without additional equipment.

Materials and valve solutions. HoReCa kitchens typically use faucets with brass bodies and chrome plating or stainless steel elements. These materials better withstand hot water and cleaning chemicals. Quality ceramic cartridges and precise threaded connections help maintain consistent flow and reduce leakage risks during heavy use.

What to check before purchasing

Choosing a two-hole faucet starts with understanding the needs of the specific kitchen. Consider how intensively the faucet will be used, the size of cookware and the layout of the sink or worktop. In professional kitchens it is worth choosing a solution that combines durability, ergonomics and easy maintenance.

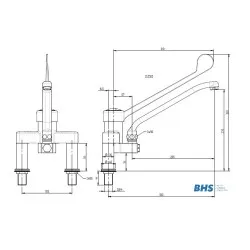

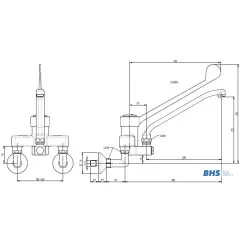

Spout and installation parameters. To avoid issues during installation, measure the sink’s hole-center distance, diameters and surface thickness. Spout height and rotation should match pot sizes and working habits to avoid restricted movement or excessive splashing.

- hole distance and diameter to fit the sink correctly;

- spout height and rotation based on cookware size;

- material and coating durability for heavy-duty use;

- compatibility with water filtration systems and pipe connections;

- recommended operating pressure range for the model.

Practical comfort. Handle shape and movement resistance matter in professional settings. Grippable handles with clear resistance help staff adjust water flow quickly even with wet hands. Fewer complex elements make the faucet easier to clean and service.

Care and use in professional kitchens

Regular care extends faucet lifespan and reduces downtime. Non-abrasive cleaning agents keep chrome or stainless steel surfaces in good condition. After busy shifts, wiping the faucet helps prevent buildup of dirt, grease and water stains.

Water quality. Limescale buildup affects flow and can shorten the lifespan of valves, cartridges and aerators. Filtration systems help reduce minerals and maintain consistent faucet performance.

Preventive maintenance. Check seals, connection tightness and spout movement periodically. If dripping, unusual noise or inconsistent flow appears, timely cartridge or seal replacement solves the issue before major repairs are needed.

BHS service and technical support

BHS provides professional service and technical support for two-hole faucets used in HoReCa kitchens. Specialists help select suitable models for preparation areas, dishwashing stations or auxiliary sinks based on sink size and water connection layout. Spare parts are available for valves, spouts, seals and other components that wear out under heavy load.

BHS works with a wide range of HoReCa equipment, including kitchen appliances, dishwashing equipment, refrigeration units, espresso and vending machines and various household devices used in professional environments. This enables consistent solutions that ensure smooth operation across all kitchen systems.

Fast spare-part delivery and expert consultation help prevent downtime. If needed, BHS can recommend installation and connection solutions to integrate a two-hole faucet safely into an existing water system.

Frequently asked questions about two-hole faucets

How do I know if a faucet fits my sink?

Compare the distance between the sink holes, their diameters and the surface thickness with the faucet specifications. Also check the type of connection and hose length, and when needed consult BHS specialists or compare measurements with the technical drawing.

Which material is best for a professional kitchen?

Professional kitchens usually choose brass faucets with high-quality chrome plating or stainless steel components. These materials tolerate hot water and frequent use well. Durable seals and ceramic cartridges are essential for reliability.

How high should the spout be for a commercial sink?

Spout height should match cookware size and daily tasks. For large pots and dish racks, tall spouts around 250–350 mm are common, while compact areas require lower spouts around 150–250 mm. Ensure enough clearance above the tallest pot.

How to extend faucet lifespan in intensive use?

Regular cleaning with non-abrasive agents, using water filters and timely replacement of cartridges or seals help extend lifespan. Avoid applying excessive force and monitor early signs of wear.

Can a two-hole faucet be connected to a filtration system?

Yes, if the filter’s connection size and pressure range match the faucet’s requirements. Check technical documentation to ensure the filter does not restrict water flow excessively, and consult BHS when needed.