Automatic faucets for HoReCa kitchens

Automatic faucets in professional kitchens support hygiene, a steady workflow and accurate water control in intensive dishwashing areas. Sensor activation allows water to flow only when hands or cookware are placed near the outlet, which is convenient when handling wet or greasy items. This reduces the need to touch handles and lowers the risk of cross-contamination.

Dishwashing stations in restaurants, cafés and catering kitchens often process large quantities of items in short cycles. Automatic faucets help keep the workflow smooth because staff do not have to search for handles or adjust hot and cold water manually. This is particularly useful when several sinks or rinsing points operate at the same time.

Sensor-operated taps are commonly used in pre-washing sinks, preparation areas and zones where pans, pots and other large utensils are rinsed frequently. Choosing a suitable model helps keep the working area organised, as there are no protruding handles or additional valves that may obstruct movement around the sink.

Main functions and construction

The core of an automatic faucet is the sensor system. In professional environments, infrared sensors are most common; they detect hands or objects within a set distance. Sensitivity can typically be adjusted to ensure stable performance even when lighting conditions or movement patterns around the sink change.

The body is usually made from stainless steel or chrome-plated brass, materials that withstand moisture and frequent cleaning with professional detergents. Water channels and valves are designed to handle different temperatures when rinsing greasy cookware or equipment parts. Some models feature built-in thermostats to help maintain comfortable water temperature and avoid accidental activation of very hot water.

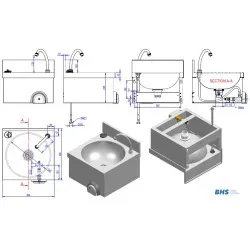

Certain faucet models are designed for installation on the sink edge or worktop, while others are mounted in the wall, freeing space and simplifying cleaning around the sink. In professional kitchens, these faucets are often combined with pre-rinse sprayers, rinsing tanks or baskets that speed up dish preparation before loading into dishwashers.

Flow restrictors and aerators are important as well; they stabilise the water stream and can help reduce consumption. These components are particularly relevant in large kitchens where teams use water continuously throughout the day.

How to choose the right model

The selection of an automatic faucet starts with understanding the workload and workflow of the dishwashing zone. If several people work at the same station, precise sensor response and adjustable reaction distance are important to avoid accidental activation. It is also necessary to consider whether the faucet will be used only for handwashing or also for rinsing large cookware.

The next factor is installation type. Deck-mounted solutions are practical when sinks and work surfaces are already in place. Wall-mounted or concealed installations are often chosen for new or renovated kitchens, where pipework can be planned in advance. It is essential to consider available water pressure, connection points and compatibility with the existing sink.

Professional HoReCa operations require easy access to temperature control, flow settings, filters and seals. Below are the key criteria that help narrow down the selection:

- Sensor type, reaction accuracy and adjustment options for intensive environments

- Body material and durability against frequent washing and impacts

- Installation type and compatibility with the sink or work surface

- Flow rate, restrictors and temperature control options

- Access to maintenance, spare parts and service support

It is important to choose a model that matches the kitchen’s workflow. Heavy-duty options with clear sensor zones are useful in dishwashing areas, while handwashing stations may prioritise a softer flow and a more compact design.

Cleaning and maintenance

Automatic faucets reduce direct contact with surfaces, but regular maintenance remains essential. Moist kitchen environments promote limescale buildup, which can affect sensor performance and water flow over time. Regular cleaning of aerators, filters and visible seals is recommended.

Limescale removal typically requires detergents suitable for stainless steel and brass. It is important to follow manufacturer instructions to avoid damaging the coating or sensor window. A clean sensor surface ensures reliable detection and stable flow.

Many models offer settings for sensitivity, activation delay, shut-off delay and maximum flow time. These functions help adapt the faucet to real working conditions. If the sensor becomes too sensitive or insufficiently responsive, checking the settings is usually the first step before investigating potential faults.

Professional maintenance helps detect worn seals, clogged filters or damaged components early. This reduces downtime and ensures that automatic faucets remain reliable even during peak kitchen hours.

BHS service and technical support

BHS provides professional service and technical support for automatic faucets and other HoReCa equipment in Estonia. Specialists help identify suitable solutions based on kitchen layout, workload and existing installations. When needed, installation, adjustment and on-site testing can be arranged.

The service includes diagnostics, warranty and post-warranty repair, and preventive maintenance for faucets, dishwashers, pre-rinse sprayers and other kitchen systems. This is important for restaurants, hotels and catering operations where every hour of downtime affects service quality.

A wide range of spare parts is available for kitchen and dishwashing equipment — from seals and aerators to complete valve assemblies and sensor modules. Parts are usually delivered quickly, helping restore equipment operation without long interruptions.

Frequently asked questions about automatic faucets

Which sensor technology is most suitable for a professional kitchen?

Professional kitchens most commonly use infrared sensors that detect hands or objects within a defined distance. They are accurate, durable and reliable in changing lighting and high-moisture environments. Adjustable sensitivity helps tune the faucet to specific working conditions.

How often should an automatic faucet be serviced?

Service frequency depends on water quality and workload. In intensive HoReCa kitchens, aerators, filters and seals should be inspected several times per year. In hard-water areas, more frequent checks are advisable.

Do automatic faucets help reduce water consumption?

Automatic faucets can help reduce water usage because the flow activates only when presence is detected. This prevents water from running when staff step away. Flow restrictors and aerators contribute to additional savings.

What should I do if the sensor is too sensitive?

If the sensor activates from accidental movement, sensitivity and reaction distance should be adjusted. Extending activation delay may also help. If adjustments are ineffective, reflective surfaces or strong light sources in front of the sensor should be checked.

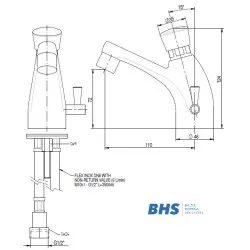

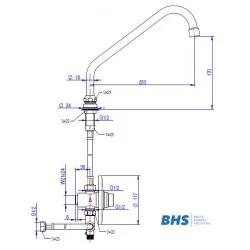

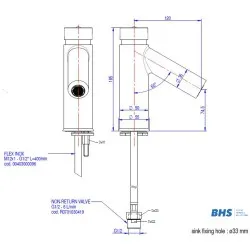

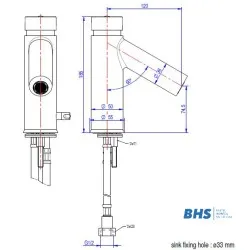

What is the typical installation scheme for an automatic kitchen faucet?

A typical installation requires hot and cold water connections, proper seals, sink or wall mounting and a power supply for the sensor if it is not battery-free. Installation must follow manufacturer guidelines to ensure tightness, steady water flow and safe operation.

/ARES021-250x250w.webp)

/ARES021_ING%20(1)%20Copy-250x250h.webp)

/ar19-250x250w.webp)

/ARES19BHS-250x250w.webp)

/are19kit-250x250w.webp)

/ARESKITPDF_BHS_1-250x250w.webp)

/a058-250x250w.webp)

/a058v2-250x250w.webp)

/a055-250x250w.webp)

/a055v2-250x250w.webp)

/a070-250x250w.webp)

/a070v2-250x250w.webp)

/a066-250x250w.webp)

/a066v2-250x250w.webp)

/a080-250x250w.webp)

/a080v2-250x250w.webp)

/a061-250x250w.webp)

/a061v2-250x250w.webp)