Apollo high-pressure spray use in professional kitchens

The Apollo high-pressure spray supports fast and efficient pre-rinsing in professional dishwashing areas. In kitchens where pans, pots, bowls and buffet dishes circulate constantly, this spray accelerates workflow and helps staff manage intensive shifts. Restaurants, cafes and catering services often rely on it to remove grease, sauces and food residues before dishwashers take over.

Monolith spray solutions usually deliver stable flow and an even jet, helping maintain a consistent pace, especially when handling large volumes of soiled dishes. Reliability and durability matter, ensuring uninterrupted kitchen operation without unnecessary pauses.

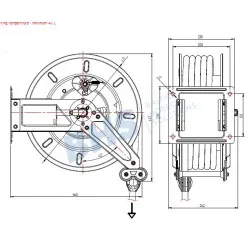

Construction and main features

The Apollo spray is built from durable materials suitable for professional workloads. Stainless steel resists corrosion and simplifies cleaning, while the flexible hose allows free movement above sinks and dishwashing tables. This combination ensures safe handling even when the spray is activated hundreds of times a day.

The nozzle creates a dynamic and concentrated jet that helps loosen hardened residues. An ergonomic, non-slip handle ensures controlled movement in scenarios requiring intensive rinsing or angled cleaning. By combining pressure, mobility and nozzle efficiency, the spray becomes a central tool in the washing zone.

Work comfort and usage scenarios

Chefs and dishwashing staff use the Apollo high-pressure spray when fast, intensive pre-rinsing is required. Typical cases include pans with burnt oil, dough containers from preparation zones and frequently used barware. The spray reduces preparation time and limits the need for additional tools because most residue is removed by the water jet.

The flexible hose reaches dishes from any angle, which is especially helpful with large sink blocks and dishwashing counters. This makes work more rhythmic and less tiring during long shifts. Ergonomics and mobility also reduce physical strain, as handle movement is usually smooth and intuitive.

What to check before purchasing

When choosing a high-pressure spray, compatibility with existing sinks and dishwashing areas should be evaluated. Important considerations include connection points, water pressure and installation height. Kitchens with high dish turnover benefit from a longer hose, while compact spaces may require a shorter option.

Nozzle and handle construction is crucial, as these components face the most intensive use. Maintenance and spare-part availability affect daily operation because professional kitchens experience faster wear. If the kitchen handles heavy or burnt residues, a stronger nozzle helps shorten pre-rinsing time.

- Compatible mounting dimensions and connection points

- Hose length matching dishwashing area size

- High-quality materials, especially stainless steel and seals

- Ergonomic, non-slip handle for regular use

- Easy spare-part availability and quick replacement

BHS service

BHS provides technical support and spare parts for professional dishwashing areas, including high-pressure sprays, hoses, handles and nozzles. The offer includes standard components and parts suited for Monolith solutions.

The BHS team assists with selecting suitable components, as well as providing guidance for installation and replacement. Fast delivery and spare-part availability help maintain uninterrupted operation in high-demand kitchens where downtime impacts overall service.

Frequently asked questions about Apollo high-pressure sprays

What water pressure is usually required for the Apollo high-pressure spray to work effectively?

A stable and sufficiently strong pressure is usually required so the nozzle can create a dynamic jet for intensive pre-rinsing in a professional environment.

Which dishwashing tables and sinks is this model typically compatible with?

The spray is usually compatible with professional sinks and washing tables used in HoReCa environments, provided the connection points match.

How often should seals or nozzle parts be replaced under intensive use?

Seals and nozzle components typically wear faster under heavy use, so regular inspection and replacement as needed is recommended.

Does hose length affect water flow pressure in professional kitchens?

A longer hose may reduce flow dynamics, so selecting a length suitable for the kitchen layout and workflow is important.

How should the handle and nozzle be maintained to extend their lifespan?

The handle and nozzle should be rinsed and cleaned regularly, and seal condition should be checked as needed to ensure safe operation.

/sr023-250x250w.webp)

/sr023v2-250x250w.webp)

/sr34a-250x250h.webp)

/sr34av2-250x250w.webp)

/sr18a-250x250w.webp)

-250x250h.webp)

/sr31a-250x250w.webp)

/sr31av3-250x250w.webp)

/s32-250x250w.webp)

/sr35a-250x250w.webp)

/sr35av2-250x250w.webp)

/s33-250x250w.webp)