Hot dog counter refrigerator in foodservice

A hot dog counter refrigerator combines a work surface for assembling snacks with an undercounter cooling compartment that keeps sausages, buns and toppings at a safe temperature. This equipment is commonly installed in gas stations, cafés, fast food operations and takeaway kiosks, where rapid service and compact workflow are essential.

In high-traffic gas stations, a hot dog counter refrigerator helps maintain a consistent offer throughout the day without unnecessary product transfers. Cafés and fast food points benefit from the ability to manage heating, topping preparation and serving from a single compact workstation.

Catering teams use these units in buffet lines or temporary serving stations, where stable quality and fast service matter. The chilled ingredients remain within arm’s reach, while the work surface provides efficient space for assembling hot dogs and other quick snacks.

Main construction features and functionality

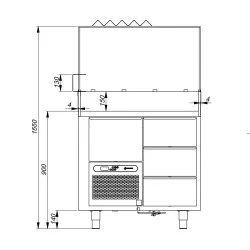

Professional hot dog counters with built-in refrigeration are usually made from stainless steel, which withstands heavy use, frequent washing and contact with food. The smooth surface is easy to clean and supports high hygiene standards.

The cooling compartment beneath the worktop is designed for ingredients requiring controlled temperature. Some units provide static cooling, while ventilated systems distribute cold air more evenly and better handle frequent door opening in intensive environments.

Many models are compatible with standard GN containers, helping organise sauces, vegetables, toppings and other components. By combining various GN sizes, the workstation can be adapted to specific menu needs.

The work surface is designed for easy access and minimal operator movement. Some models include topping displays that improve visibility and support semi-self-service layouts.

Selection criteria for professional kitchens

A hot dog counter refrigerator should match the expected workload and customer flow. Gas stations and busy fast food venues often require more powerful cooling, larger capacity and ergonomic door or drawer configurations. Smaller cafés may use compact models that fit tight bar areas.

The internal volume determines how many ingredients can be stored in ready-to-use condition. It is practical to choose a model that accommodates several GN containers at once, reducing the need for repacking. Energy efficiency is important because the equipment often operates continuously.

The cooling system type, compressor performance and noise level affect both food safety and operator comfort. GN compatibility helps maintain order and supports a smooth preparation process.

What to check before purchasing:

- overall refrigerator capacity and cooling type;

- GN container compatibility with the planned ingredient setup;

- compressor power, cooling performance and noise level;

- door or drawer ergonomics during intensive work;

- stainless steel thickness and overall build strength.

Operation and maintenance

A hot dog counter refrigerator requires regular cleaning to maintain stable cooling and hygiene. After each shift, the work surface should be wiped using food-safe cleaners. Stainless steel simplifies cleaning, but consistent care prevents odours and residue buildup.

The cooling compartment should be checked for condensate and cleaned regularly. If the unit lacks automatic defrosting, manual defrosting must be performed periodically to maintain efficient cooling.

Operators should close doors promptly, especially during hot periods, as prolonged openings reduce cooling efficiency and may affect ingredient quality.

BHS service and technical support

BHS provides technical support for hot dog counter refrigerators, assisting with selection, installation and daily operation questions. The service team works with professional foodservice equipment and understands the needs of gas stations, cafés and fast food venues.

A wide range of spare parts is available for refrigeration equipment and other kitchen units, including chilled worktables, display cases, dishwashers, espresso machines, vending equipment and selected household-type appliances used professionally.

Many clients rely on BHS service to maintain consistent performance across all cooling and snack preparation zones. Regular maintenance and timely replacement of worn parts help reduce downtime and support stable service quality.

Frequently asked questions about hot dog counter refrigerators

What is the optimal temperature range for hot dog counter refrigerators?

Most units maintain a temperature range of 2–8 °C to ensure safe storage of sausages, buns and toppings. Exact settings depend on the model and manufacturer instructions.

How much product can typically be stored in the undercounter cooling compartment?

Capacity depends on the refrigerator size and chosen GN containers. Most units can hold several GN pans with sausages, buns and toppings, supporting continuous sales during peak hours.

Are these units compatible with standard GN containers?

Most professional hot dog counters with refrigeration are designed for compatibility with GN standards such as GN 1/1, GN 1/2 or GN 1/3. Dimensions should be checked before purchase.

How often should cleaning and defrosting be done in intensive use?

Work surfaces should be cleaned after each shift, while cooling compartments require regular cleaning. Defrosting frequency depends on the unit type and workload.

What advantages does professional BHS service offer for this equipment category?

BHS service assists with equipment selection, installation, maintenance and fast repair response. Access to spare parts and expertise reduces downtime and supports consistent service quality.