Professional IceTech ice makers in the HoReCa equipment

IceTech ice makers are designed for continuous use in demanding HoReCa environments where large amounts of ice are needed in a stable 24-hour regime. Their robust stainless steel construction supports hygiene and makes cleaning easier. Consistent and predictable ice production is crucial for bars, restaurants, hotels and buffet areas.

Ice quality is influenced by integrated rinsing and filtration systems that help produce clear, dense ice. This is especially important for drink presentation and food cooling processes.

Ice types and their applications

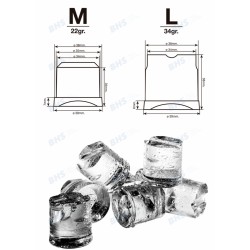

The IceTech range includes several ice types suited for different purposes. Full cubes work well in cocktails where slow melting is important, while hollow cubes provide faster cooling, which helps when handling large drink volumes. Flake ice is optimal for fresh food displays, and granular ice allows quick cooling of ingredients during mixing.

- Full cube for serving premium drinks.

- Hollow cube for fast cooling of drink components.

- Flake ice for seafood and fresh food displays.

- Granular ice for preparing mixed drinks.

Technical features of IceTech ice makers

IceTech units are available with different cooling systems and power levels. Air-cooled models suit spaces with good ventilation, while water-cooled models perform well in hot kitchens or areas with limited air circulation. Daily production capacity helps determine whether a unit can keep up with your operation.

To ensure consistent ice quality, filtration and easy-to-clean construction are essential. Automatic cleaning functions shorten maintenance time and improve hygiene in professional settings.

- Daily production capacity and bin volume.

- Cooling method and ventilation requirements.

- Water filtration system and water hardness.

- Energy consumption and cabinet materials.

How to choose the right ice maker for your business

When selecting an ice maker, consider consumption, workload intensity and available space. Compact bars often benefit from air-cooled models, while larger restaurants frequently choose water-cooled units. Bin capacity plays a key role in preventing ice shortages during peak hours.

Water quality directly affects ice clarity and taste, so filtration systems become essential equipment in professional environments.

- Determine real ice consumption during peak periods.

- Check ventilation options and suitable cooling type.

- Evaluate water quality and filtration solutions.

- Choose bin volume that matches your working rhythm.

- Consider energy efficiency and noise level.

BHS service, spare parts and technical support

BHS provides professional service, spare parts and regular maintenance for IceTech equipment. Correct installation, proper ventilation and regular cleaning help maintain stable long-term operation. The service team supports diagnostics, repairs and replacement of original manufacturer components.

BHS offers spare compressors, pumps, filtration modules and sensors that help keep ice makers running reliably even during periods of heavy workload.

Frequently asked questions about IceTech ice makers

How to choose the most suitable IceTech ice maker?

You should consider daily consumption, bin capacity, cooling method and room ventilation options to ensure stable production.

Which factors affect ice quality?

Ice quality is most often affected by water hardness, insufficient filtration and unclean equipment surfaces.

Is there a significant difference between air-cooled and water-cooled models?

Air-cooled units require good ventilation, while water-cooled units provide stable operation in hot and confined spaces.

How often should an ice maker be serviced?

In professional environments, regular cleaning and periodic professional diagnostics are recommended to maintain hygiene and production capacity.

How does BHS service support IceTech equipment operation?

BHS offers installation, diagnostics, spare parts and regular maintenance that help keep equipment running continuously.

-250x250h.webp)