The role of ice makers in bar operations

Ice quality often determines how a cocktail looks and tastes. Premium-grade ice cubes maintain the drink’s structure longer, melt slowly and allow bartenders to control temperature during intense service periods. Professional ice makers ensure consistent results even during evening rush hours and events.

Bars usually prefer equipment that produces clear, uniform cubes without air pockets, as this improves drink presentation. Consistent shape ensures predictable dilution, which is essential for cocktails with high-quality ingredients.

Many bar teams use a dedicated ice maker specifically for cocktails to keep quality stable throughout the day.

Ice cube types and their impact on drink quality

Ice makers can produce different cube sizes, each suitable for specific drinks. Large gourmet cubes are popular for slow-sipping cocktails. Smaller classic cubes are often used in long drinks, mixed beverages and lemonades.

Clarity is equally important. Cubes frozen in layers with controlled water flow usually appear clean and transparent, creating a professional visual impression. This feature is valued by bars aiming for exceptional presentation.

Some machines provide other ice shapes, such as half-moons or cylinders, but uniform cubes remain the most common choice in professional bars.

Key selection criteria for HoReCa needs

Bartenders’ requirements differ from kitchen workflows, so ice maker selection depends on operational rhythm. Production capacity, expressed in kilograms per 24 hours, is often the most important factor. Small bars typically choose 20–50 kg models, while larger venues may need 60–100 kg units.

Storage bin volume is also essential. If the bin is too small, ice shortages may occur during peak hours. A larger bin stabilises workflow and ensures continuous availability.

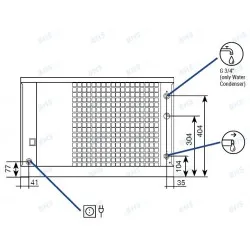

Material quality and maintenance convenience affect longevity. Stainless steel supports hygiene, while filtration systems help produce clear cubes. Cooling type, such as air or water, determines whether the machine fits the available space.

- Daily production capacity and compatibility with workload.

- Storage bin volume and refill speed.

- Cooling type and its impact on placement.

- Water filtration options for crystal-clear ice.

- Materials and maintenance requirements.

Maintenance and operational specifics in professional environments

Regular maintenance is essential for ice quality. Replacing water filters and cleaning internal surfaces prevent mineral buildup that affects flavour and clarity. Some machines offer automatic rinsing programs, simplifying routine care.

It is advisable to place the unit where airflow is unobstructed, especially for air-cooled models. Water-cooled units offer stable performance in warm and tight spaces but require higher water usage.

A simple weekly routine helps maintain efficiency. Checking water supply and cleaning the bin supports consistent ice quality.

- Placing the unit in areas with insufficient ventilation.

- Not replacing filters, which causes cloudy or uneven ice.

- Overloading the machine beyond its 24-hour capacity.

BHS service and technical support

BHS provides professional service and spare parts for various ice makers used in bars, restaurants and other hospitality businesses. The BHS team assists with installation, diagnostics and maintenance, which is crucial for equipment under high daily workload.

Spare parts such as compressors, water supply elements, sensors and electronic modules are usually available for quick delivery, reducing downtime.

BHS also advises on appropriate water filtration solutions to achieve excellent ice clarity and durability.

Frequently asked questions about ice makers

What is the optimal ice maker capacity for a small bar?

A small bar typically needs a 20–40 kg daily production model, provided the workload is steady and a suitable storage bin is available.

Which factors most influence ice cube clarity?

Clarity is usually influenced by filtered water, uniform freezing and machine cleanliness. These reduce cloudiness and air pockets.

Should I choose an air-cooled or water-cooled ice maker?

Air-cooled units suit well-ventilated spaces, while water-cooled models work reliably in hot or narrow areas but require higher water consumption.

How often should an ice maker be maintained?

Maintenance frequency depends on usage, but regular cleaning and filter replacement help maintain consistent ice quality.

How to determine whether the bin capacity is sufficient for high demand?

Adequate capacity depends on peak-time consumption. If ice frequently runs out, a larger bin or a higher-capacity model is recommended.

-250x250w.webp)