Use of full cube ice in the HoReCa environment

Full cube ice makers typically provide stable and visually appealing ice suitable for bars, restaurants and cafés. Full cube ice melts more slowly, preserving drink flavour for longer and reducing excessive dilution. During high-volume service, this type of ice helps maintain consistent quality.

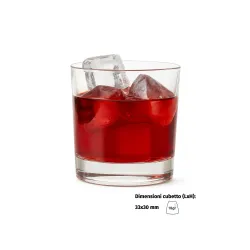

Cubetto pieno 18 g ice cubes are well suited for serving classic cocktails and drinks on the rocks. The cube keeps a clean shape, provides an even reflection and enhances drink presentation.

Properties of the Cubetto pieno 18 g cube

The 18 gram full ice cube forms dense, with a smooth structure and clear surface. Reduced air pockets allow the cube to hold temperature for longer, which is important during intensive service hours. In bar areas it helps keep drink balance stable.

This cube size usually creates fewer leftovers in the ice bin and is easy to handle, simplifying daily workflow. It maintains drink appearance and often becomes a key visual element in higher-quality cocktails.

Types of ice makers and technical parameters

Full cube ice makers come with various cooling systems and power levels. Air-cooled models are popular for compact bars, while water-cooled units are often chosen for kitchens where space is limited and heat load is high. Selecting the right cooling system helps maintain stable operation.

Important parameters for professional equipment include compressor power, water consumption, filtration solutions and bin capacity. Stainless steel construction supports hygiene and simplifies regular cleaning.

- Ice production in a 24-hour cycle.

- Bin capacity for peak service hours.

- Cooling method and ventilation needs.

- Filtration systems that improve ice quality.

What to check before purchasing

When purchasing, it is important to consider room specifics and actual ice consumption. High-traffic bars need higher capacity, while small cafés benefit from compact units providing stable cube quality without unnecessary energy use. Bin size is crucial to prevent shortages.

Safe and high-quality ice production depends on water quality, making filtration systems essential. Poor ventilation can reduce performance and increase heat load, so installation must be carefully planned.

- Daily production and peak demand.

- Ventilation possibilities and airflow.

- Water quality and filtration systems.

- Bin capacity and working schedule.

- Noise level and compressor operation.

BHS service and technical support

BHS provides technical support and spare parts for professional ice makers used in bars, restaurants and other HoReCa businesses. The team assists with installation, diagnostics and regular maintenance to ensure stable operation during intensive workloads.

The available spare parts include compressors, filtration modules, pumps, sensors and other essential refrigeration components. This support helps reduce downtime risks and maintain uninterrupted ice production.

Frequently asked questions about full cube ice

What advantages does full cube ice offer in drinks?

Full cube ice melts more slowly, maintains drink temperature and helps keep flavour balance, which is important for cocktails and drinks on the rocks.

How fast does an 18 g full cube melt, and how does it affect drink flavour?

The 18 g cube typically melts evenly, reducing dilution and helping maintain structure during long service periods.

How to choose a suitable ice maker for a bar or restaurant?

Selecting a unit requires considering production capacity, bin size, cooling method and ventilation possibilities to ensure consistent ice during peak service.

What are the most common reasons for declining ice quality?

Ice quality is usually affected by water hardness, insufficient filtration, unclean surfaces and ventilation issues.

How does BHS service support long-term ice maker operation?

BHS provides installation, diagnostics, spare parts and regular maintenance that help keep the equipment stable in the long term.

-250x250w.webp)